Facade structures for full transparency

Curtain walls connect several large glass surfaces into a single structure, many times in an invisible manner. Initially these elements were exclusively used in communal building technology but, with the penetration of the minimalistic style, it also appeared in the family home segment. Today it is the most dynamically developing branch of the closing structure market, in that these surfaces are suitable for individual solutions where only the imagination of the client and the designers can set the boundaries.

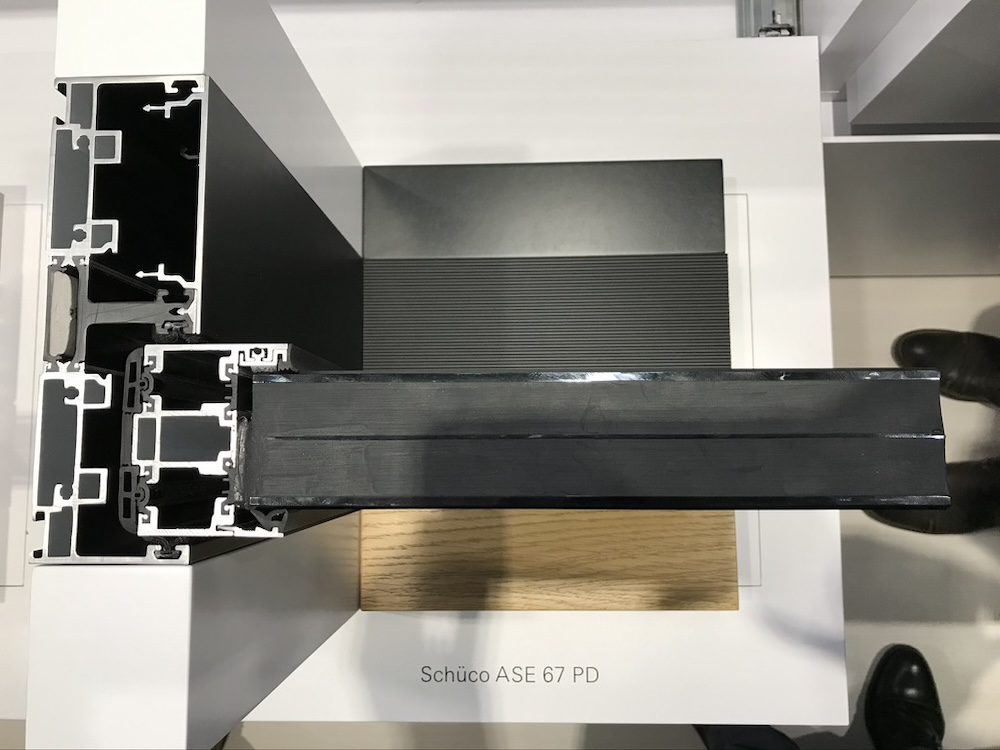

Curtain walls are space-dividing shell structures that are fixed to the load-bearing structures (slabs, facades) and are located in front of their plane. Generally, they are manufactured from large prefabricated elements, and as a result of this, a representative, greenhouse-like effect can be achieved with their use. For curtain walls, the key phrase is maximum transparency, since manufacturers today seek to connect glass surfaces with nearly invisible fastenings wherever possible. Like the other product ranges of aluminium closing systems, curtain walls first appeared in communal construction technology; they mainly used to be characteristic features of office blocks. However, these days they are a beloved choice for family homes; namely, for level height glass walls, there are situations when only externally glazed solutions can be used that serve as facade surface cover. The architectural appearance of curtain walls is a lot sleeker than traditional doors or a sliding door system, since, with a 35 to 80 mm rib, enormous glass tables, weighing even up to 1000 kg, may be installed on top of or next to each other, even in space.

Every see-through raster closing facade surface cover with external glazing is called a curtain wall. In such cases, a mounted building shell frame is fixed onto the facade and filled in with glass shields and then it serves the transparency function, either in fixed or opening versions. These structures may turn in the roof’s plane; in this way, the result is full lighting, even in the appearance of a staircase, a nice living room ceiling or a loft. Curtain walls are one of the most dynamically developing areas in construction material technology. Namely, these systems may not only be built from a standard aluminium system frame but also in a completely unique arrangement. For example, one can see the tensioning structure solution in iconic office blocks, when, from the interior or exterior, a stainless steel rope frame is built and the glass panels are fixed onto it in a point-like manner, mechanically or with glue. The need to hide the glass supporting frame is increasingly prevalent in the industrial and the family home segments and so developments mainly go into this direction. Apart from resistance to wind and other weather effects, curtain walls must fully meet insulation and leakage demands.

For family homes, the use of curtain walls is recommended if they present a broadly homogenous surface with all other structures, in terms of style, appearance, rib frame, width and depth, and for glass roofs or floorplans where there are many breaks and numerous unique shapes. The general implementation takes place by mounting a glass shield onto a structurally engineered dimensioned, aluminium carrying rib frame, using a special laying system. The rim at the edges of the glass shields may be visible, hidden or a combination of these. Accordingly, where glass meets glass, only black silicone is applied as sealant, which results in a structural look. In this case we use either point-like hidden or mechanical (disc) fastenings in the line that is sealed with a certified special material. If the architect requests not to have any projecting element on the glazed facade, then there is not really any other installation method other than the structural glass walls that allow for this solution.

Curtain walls have several exciting characteristics. Since they are usually surface-treated aluminium structures, the interior designer can lend a unique construction style and shape to the building by experimenting with the depth, colour and style of the rib frame. Apart from this, the sectioning of a completed curtain wall can be amended, so in a couple of years a fixed structure may be transformed into an opening one by simply integrating an additional rib or window shield. Namely, if the function of a building changes, e.g. from a flat to an office, and sectioning walls have to inserted, the curtain walls are serious help, since new elements can be integrated without any damage.

However, curtain walls are a far more pricey solution than standard closing systems, since their installation technology and material culture also represents a much higher value category. The material cost of the rib frame is already higher in nominal terms than that of a traditional fixed window frame. Let’s imagine a facade designed with a curtain wall. If they integrate a window into the same area, it is mounted into the wall opening or its surroundings, while a curtain wall must be installed in any case in front of the wall, hanging out of the entire frame system, loaded on dimensioned support structure elements. This requires a fastening technology and insulation that are a lot more complicated; in addition to this, thermic movements and unique nodal connections must also be considered. Such a structure therefore requires not only a longer design time but involves higher material and installation accessory costs, and so it is a much more expensive technology. However, a significant transparency may be achieved by using it, and the nearly invisibly connecting glass surfaces can lend a magical appearance to the building.

MoreNews