KAV production unit in Kisbér

Our company has started an investment in Kisbér in Komárom-Esztergom County. In addition to the production tasks, we will also carry out a number of preparatory and design work tasks at the factory’s 3-acre site and their offices near the city. Károly Lovász, Managing Director of KAV, gives an insight into the possibilities and future plans of the new special windows and doors factory.

KAV has purchased a much larger and more complex building compared to the previous one. What can you say about this property?

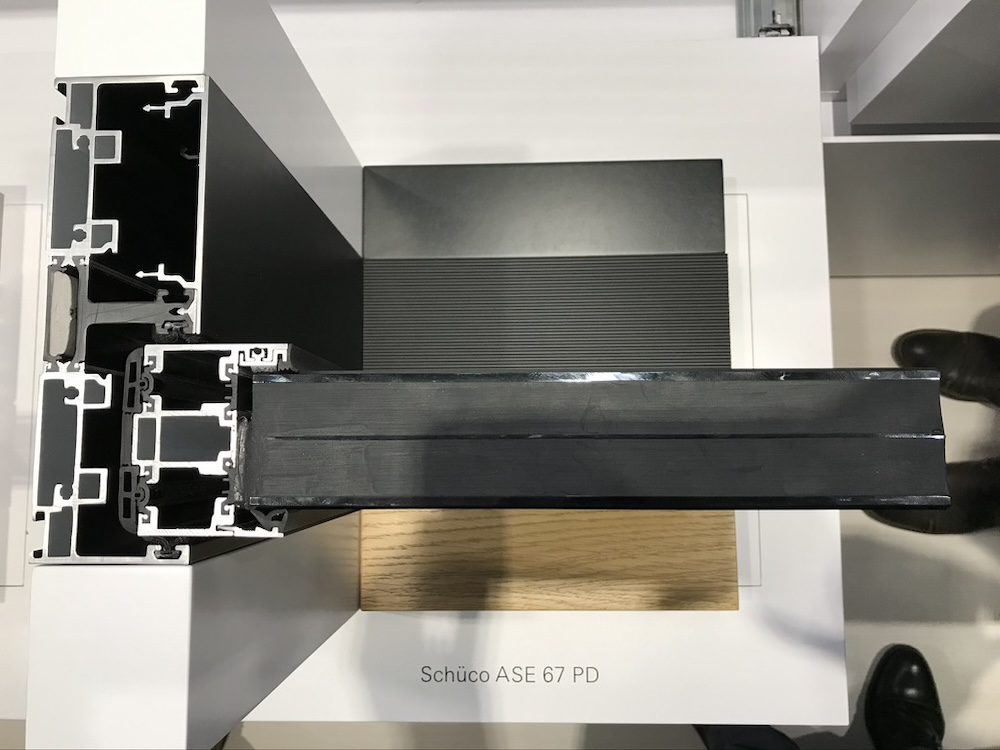

Our plants so far have always been leased and we have faced two problems all the time. Neither their size, including ceiling height and floor space, nor their external storage space were adequate for customers’ requirements. Unfortunately, there is a tendency in the construction industry for negotiated construction and implementation times to be delayed, so we have to store our products somewhere safe, because they are always manufactured on time. What’s more, with the increase in export orders, much larger quantities of raw materials are shipped at the same time than we have been working on so far, and the combined effect of these two increased the need for production and storage space dramatically. Our special glass technology work is also increasing during the manufacturing period, as while our competitors process mostly aluminium profiles and deliver the glass to the site for installation, we have many products and engagements where we have composite adhesive technology tasks with glass panels. In the new plant, the placement of these glass panels during the critical glueing and subsequent resting periods is so far resolved. The expansion of the production area also became justified as we needed a significant expansion in. In addition to the new tailoring and CNC machines we bought last year, we had to order another more advanced machining centre from Germany. As a novelty, we would like to make a pole change between the Budapest headquarters and the Kisbér site, as part of which we are going to carry out more and more work – technical preparation, drawing, production preparation and development – at the manufacturing plant, because of the suitable IT background and the quantity and quality of offices.

Why did you decide that some of the intellectual background work should be done in Kisbér?

Again, I have to point out that what we make and do is very different from the usual work in this industry. Our future products and new developments, which will debut in early 2020, require significant intellectual capacity at the manufacturing site. We also had to find a solution to the labour shortage, since we can find very few people in certain professional fields in Budapest, but the signs in Kisbér are very positive. Of course, the change will not happen overnight, but will take place gradually.

How conscious was the decision to have the new plant in Kisbér and in this region?

We definitely wanted to stay in the vicinity of Mór, since our current colleagues commute from there. Kisbér is also a practical choice because it is located a lot closer to Western European export areas in terms of existing expressways. I don’t keep it a secret that the future expansion of the roads (13 and 81) into motorways also influenced us, since this will be done right near our new site. In addition, Komárom and Győr are both within easy travel distance, which is also useful in terms of attracting a workforce.

I think the change of location is a very good indication of the development of a company…

Indeed, the reason for our relatively fast site relocations is that we are always a little bit ahead in terms of our sales and product lines than we are able build around ourselves in infrastructure. So our commitments are a little ahead of our current resources and capabilities. But I believe in this step-by-step thinking. We have not filled a huge plant with imaginative and hopeful work, but expand as needs arise. However, with our products under development, we feel that something is about to begin when we need to follow up expansion immediately. There is free space here where we can even build new production units. I can also say that if there is a market demand for this, you need to go up the stairs two or sometimes five at a time. This requires a factory and a site where we will be able to react very quickly in terms of production and gain new production space by building a new hall. I see the key to our future and the livelihood of our employees in developing new products alongside our existing responsibilities.

What is this current plant capable of?

If you look behind the classic spectacles of the Hungarian aluminium window and door manufacturers then I have to say that this plant should be perfectly sufficient for sales of up to three billion a year. Due to our glass technology and our special glass-related needs, especially for new products, I can already see that the current building will only be a starting interface, and we will certainly need to expand soon. Now we did not want to make any investment that is beyond the capabilities of the company, as it would jeopardise our stable market presence and expansion. For us, this space is currently the most exciting in terms of ceiling height, so now we can move even the largest standard triple-layered glass panels (in 7 by 3-metre sheets), while the variable interior height and length shelving system allows for pallet storage for raw materials. The plant has a modern heating system, which allows us to perform complex and interlocking glueing technology tasks, with 24/7 constant temperature and humidity control. This is a major improvement over our manufacturing competence so far, and what is most promising to me is that both our machine and building infrastructure are able to comply with the latest IPAR 4.0 production system.

MoreNews