Choose big aluminium windows and doors!

It is worth choosing large doors and windows.

The use of aluminium doors and windows in family homes allows increasingly large glass surfaces to appear in residential buildings. Because we spend a large part of our time indoors, high-transparency aluminium windows and sliding doors help to create an almost direct connection with the environment. We discussed with Károly Lovász, the managing director of KAV Hungária, why it is worth choosing large doors and windows.

Is it true that only small size premium windows can be bought at an affordable price, and in good quality?

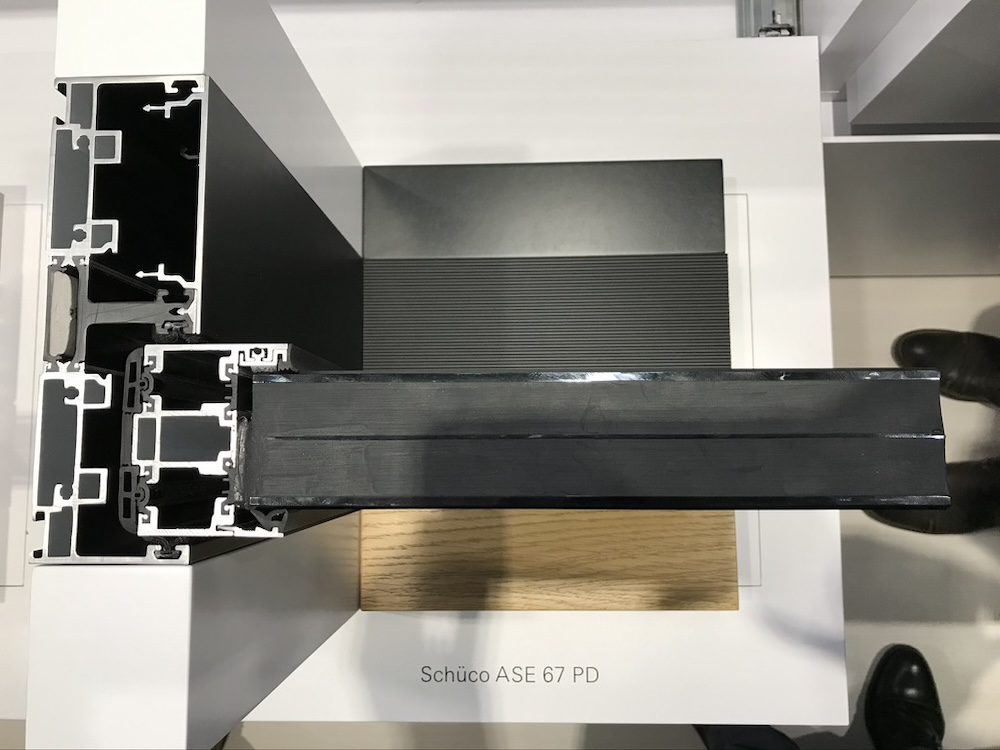

To this, the answer is clearly no; there are now a number of aluminium profile systems that offer large doors and windows at affordable prices. The fact that this issue has arisen is due to the situation that there are significant market players in the production of plastic or wood products who suggest this, as the range of products they produce or market is much more limited. Indeed, a plastic window cannot be expected to have the same width and/or height as aluminium, and they cannot use inertias, narrow and filigree solutions, heights and sash weights with wood like with aluminium or fibrous composites. With other raw materials (such as steel) it is not possible to achieve the forming properties of aluminium arising from extrusion, while retaining its application possibilities. However, everything has its place in the world.

We find that with the motto “dare to be small” some are trying to squeeze people into a sort of sorting and sizing template, between narrow possibilities, which also affects architects. Professionals start again to design hole windows as a result of misinformation, although domestic and foreign trends, and framework and flat glass manufacturer developments are not moving in this direction either. In our age, the need for information is increasing in all areas and, in the case of glass panel sizes, this is manifested in such a way that we want to maximize the exchange of information between the outside and the interior.

When choosing doors and windows, can this be achieved by maximizing size?

Yes. Since we spend a large part of our lives at home indoors – in a family home approx. 90 percent, almost 100 percent in a condominium – so with larger glass surfaces I can get a lot more information from the outside in terms of weather, light and landscape beauty, for example. Let’s see what the trend is in office building technology: they now produce almost exclusively glass façades, as we are able to build a façade of aluminium in a quantity and quality that is not feasible with any other material. Glass technologies and coatings have made it possible to produce glass surfaces that exceed energy-critical limits and are already profitable in family homes. Not to mention the mechanisms, designs, hardware technologies and motors that move the structures, which are specially developed for the movement and operation of large glass surfaces.

But let’s dare to be small, say some companies operating in the world of PVC and wood. After all, they feel they can’t follow these trends with their existing resellers. Although they have been trying for many, many years to make their cheaper and less knowledgeable PVC and wood-based products more valuable with cladding solutions to make them look like aluminium from the outside. But what kind of need do we want to satisfy with this procedure? This is typically the category of “solve it somehow; it should just look beautiful on the outside”. I don’t want to build in this way, and I wouldn’t even encourage anyone to build like this.

If trends go in the direction of large glass surfaces, I would not advise the opposite to builders, as this will backfire significantly negatively upon selling. As the manager of an innovative company, I have to propose solutions that result in ceiling height and movable glass surfaces and glass façades that really point in the direction of the trend. These could even be made of PVC with proper development; hybrid material solutions, but not surface beautification. Aluminium and steel allow for the filigree look to be realised almost indefinitely, but the segment of customers who like a thicker, more honest structural window and door structure, even for ceiling height glass surfaces, is also significant. Why don’t we serve them? Fortunately, there is also a wooden door and window manufacturer trading in Hungary that innovates and proactively tries to satisfy customer needs in a professional way.

Can doors and windows be both large and affordable?

No need for a door or window to know everything. When designing a hole windowed house, these structures must always be openable so that they can be ventilated; they cannot be fixed, and hidden sash designs are rare in these price categories, resulting in a significant difference in glass surface between fixed and openable structures.

I encourage customers to use heat recovery mechanical ventilation in their family home from the outset because, in addition to their significant physiological value, they will experience cooling and heating cost savings. Thus, it is completely unnecessary to open all the structures, to let all the windows open and tilt, or to install them with hardware and handles. This already reduces the price. There should be an openable surface in each room, but we should try to design and install the remaining structures in such a way that they are the most cost-effective, with the same appearance. The cheapest is when I put a glass panel in a fixed frame. It is not the glass in the door or window that is expensive, but its frame, its placement and node design and its shielding connection.

With a careful, thoughtful design process, I can significantly reduce my door and window costs. We also see this in our own houses, because in buildings where we are involved in the planning process in time, in the junction planning, we can build them much cheaper. We shifted the ratio of openable to closed surfaces towards fixed surfaces. I don’t have insect nets because I don’t open as many windows, as mechanical ventilation provides fresh air. However, if I want to go out, I have the option to step out onto the balcony or terrace. With a hole window solution, I have to open all surfaces. The cost of installation, installation aids and blinds is added to this. Therefore, and due to its durability, it may be cheaper to have a specifically more expensive aluminium door and window system for a large area.

In the case of lift-and-slide structures of a certain size, 2800-3000 millimetres high, the price per square metre is also better for aluminium. And if you have to use an opening method where I have to open a 3 metre high balcony door without a dividing rib, it can obviously be solved only from aluminium. It also shows that at large size limits, things are definitely decided in favour of aluminium.

And there is another important aspect, the value of the building. Let’s look at family homes built in the ’70s, what’s the value there? Let’s look at the tower-arched dwellings built in the early ’90s, which do not represent a significant material value today either. What is sought now? What is it where the location of the settlement / plot does not determine the purchase price of a second hand family residential property? Bauhaus houses with large glass surfaces and steel windows, built in the 20s. They are conserved, or Bauhaus-style façades are built into new houses. A really thoughtful, imaginative, large glass façade will have value in 100 years.

Aluminium doors are bolder, more filigree and maintenance-free. Surfaces do not need to be handled other than washing them with detergent water. They are also easy to maintain, as the fittings are covered and the structures are equipped with motors and electronics that can be serviced by the largest aluminium system suppliers – based on the example of car parts manufacturers – for convenient maintenance for 30-40 years. I encourage everyone to dare to design a façade a little more boldly. It’s worth it in the long run.

MoreNews