Aluminium window and door development trends and tendencies

Ever-increasing dimensions, ever-increasing load capacity, automation and integration of structures. These are what Reynaers’ staff see as the most striking trends in the development of aluminium windows and doors. We spoke to Zoltán Nagy, Head of Reynaers Aluminium Hungary, and Gergő Hajas, Sales Support Engineer at Reynaers Aluminium, about their experiences and trends they saw in 2021.

What are your main impressions as an international company and how do you assess 2021? And to what extent was it influenced by the pandemic that’s now in its second year?

Zoltán Nagy: For us, 2021 was a good year; we massively increased our turnover. We were involved as a contractor in several large projects. I believe that the construction industry hasn’t been affected or slowed down significantly due to the pandemic. In 2020, when it all started, there was a standstill because nobody knew exactly how to deal with it. However, as I can see, by 2021, everyone in the construction industry had learned to live with it and we keep moving forward. Within Hungary, in 2021, the restrictions were no longer heavy enough to limit movement within the country significantly. What’s more, we were even able to take interested customers to our showroom in Belgium. On the other hand, international trade events were cancelled, so we weren’t able to meet up and establish contacts in this way, while the number of international trips within the company also fell.

Does it cause any problems?

Z. N.: It hasn’t caused any problem for the business; but I, personally, miss meeting colleagues with whom I used to have a more regular relationship. We were lucky that we were able to establish a personal professional relationship with our colleagues abroad before the pandemic, and we were able to deepen this relationship by phone, e-mail or online meetings. It was easier in this way because we had something to build on.

Due to difficulties in the supply chains, there was a shortage of raw materials in the construction industry. Has this affected you?

Z. N.: Yes, it has. Supply chains have indeed been damaged by this situation, but not directly by Covid, as the movement of goods has always been allowed, even during the most severe lockdowns. Instead, I see that the supply chain situation was made more difficult by incentives to mitigate the economic impact of the virus. Governments have poured money into certain areas of the economy to boost it, so there has been such an increase in aluminium products, for example, that the supply chain was no longer able to deal with it.

And now you shouldn’t think about just construction industry aluminium products, but also products for the automotive and aerospace industries. Currently, globally, about 50% of aluminium production is concentrated in China so, if anything happens there, the entire world will feel it. The European Union has imposed anti-dumping duties on a large share of aluminium products from China, because they have tried to import them into the European market at practically below cost price in order to gain market share, and the Chinese State would have compensated them for their losses. This was offset by the customs duty imposed, which reduced Chinese imports. So, on the one hand, there was a surge in demand and, on the other hand, the supply side declined, and these two in combination had a very serious impact on supply.

And how did this manifest for you?

Z. N.: It was basically reflected in delivery times. In the case of standard products, which we could deliver from the warehouse in, say, two weeks, surface-treated, the delivery time for those products increased to three to four weeks. And for custom products, where custom press manufacturing was needed, this period extended from two months to up to five months.

How could you handle this?

Z. N.: It depended on the situation. There were customers who were relaxed about this.

Obviously we tried to renegotiate the terms, and we kept constant contact with our partners to see what delays we could foresee. There were cases when these delays could be accommodated. But where the contractual deadlines could not be changed then a more difficult situation emerged as a result.

You said you closed a very positive year in sales. What was this due to?

Z. N.: The company had a significant increase in sales globally and also in the Central European region, which includes Hungary. We’ve also seen significant growth domestically. Thanks to the stimulus to boost the economy, a lot of construction work started or abandoned construction works restarted last year. As such, we’ve seen a sudden huge increase on the demand side.

What have you seen in the family home market in terms of aluminium windows and doors?

Gergő Hajas: The family home aluminium door and window segment is expanding further, with increasing demand for frameless sliding door systems.

Z. N.: I also think, by the way, that the share of aluminium doors and windows in the family home segment is increasing. A part of the Hungarian population has a growing disposable income, which means that there is now a demand from those with purchasing power for windows of higher quality, higher performance and a longer life.

As I know, your company has numerous product developments. In what direction are these developments going?

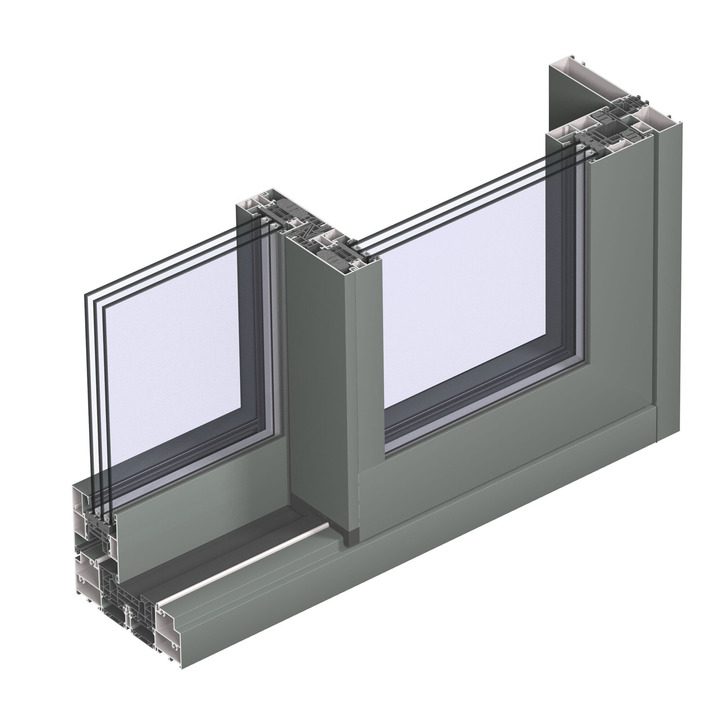

G. H.: The year before last, we presented our MasterPatio aluminium lift and slide system, which is unprecedented in the market. We have improved this product further and extended its field of application. So to speak, the second phase has been launched: a three-rail alternative is now available, as well as a fixed-sliding-fixed division mode, and two versions of the stormwater runoff system, in a concealed and a visible design. It became a product line with expressly high value and a very good price.

What did high value mean?

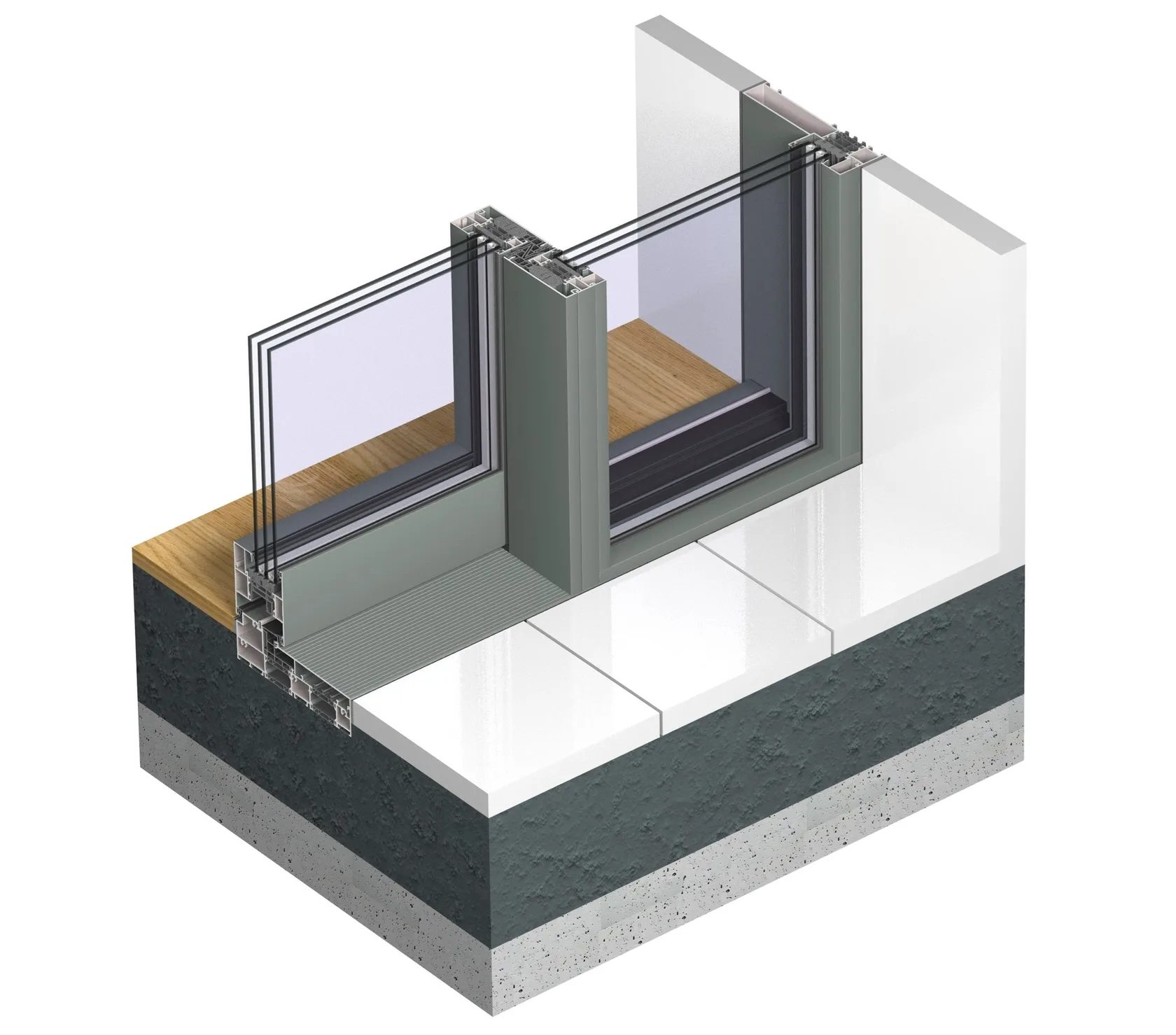

G. H.: Despite not being a frameless system, in a single track version the casement and fixed pane can be made almost entirely concealed, so that the sash is only visible when it’s moving. It‘s a very filigree, very modern lift-and-slide system that meets today’s requirements, in terms of dimensions as well. The wing can reach up to 3,600 millimetres in height, and now, with the new hardware, a wing can weigh up to 500 kilograms. Another innovation is that our unique Purity design handle is now also available for the MasterPatio, so that this product has also opened up further towards the premium category. And a concealed wing design also became available in the MasterLine 10 system. This is the “sibling” system to MasterLine 8 with higher thermal insulation capabilities, actually achieving a passive house rating. For Hi-Finity, we’ve developed an insect net system that can be opened to a width of 1 metre. Furthermore, we already have curtain wall integrated window systems, opening outward, and this isn’t really the family home segment.

What determines the direction of your product developments?

Z. N.: Basically, the development is set up in such a way that the central development team consults the different markets in specific product categories and collects market feedback, namely the needs coming from the manufacturing partners and end users. These needs go through an evaluation process. We’ll select development directions that have a market rationale, and really ride the trends that can be seen in architecture in the long term. In the family home line, we see that architects increasingly think of combining different structures. The earlier architecture that used to characterise buildings, namely that there was a separate door; a separate window; a separate patio door – these are becoming increasingly interconnected and integrated with each other. They want to integrate a ventilation wing next to the lift-and-slide door, and they also want to put a ventilation wing next to the entrance door. They would also like to extend the aluminium lift-and-slide door with a fixed or a tilting window or balcony door. At the moment, they have to sort out integrating these, which MasterPatio aluminium sliding doors are capable of doing, due to their design. The system has been developed so that it can be easily integrated with a specially designed coupling profile, Masterline 8 or Masterline 10 systems, without the need to develop a custom technical solution for each case.

G. H.: What’s also very important is automation. This is also in great demand in the family home segment. A motorised version of the MasterPatio will be launched this year. The further increase in Sobinco’s concealed hardware’s load capacity was another interesting update, though less spectacular. Earlier, the maximum wing weight for the Invision Go was 90 kilograms; it’s now increased to 130 kilograms and, for the Pro, the previous maximum load capacity of 170 has been increased to 200 kilograms.

Are these what customers in Hungary look for in the family home line today?

Z. N.: In the family home line, on the one hand, they want to have larger continuous glass surfaces to make the building transparent, and they are also thinking about interconnected elements. And, for entrance doors, there’s a very strong trend towards asymmetrically hinged pivot doors, also known as swing doors. In the past, it was common for customers who wanted a large entrance door to have a double-leaf door, with a main leaf and a smaller opening side leaf. Now, however, by integrating a pivot door, we can give a building a completely different look. In the case of pivot doors, customers also increasingly look for larger dimensions, and in the Reynaers system this can reach even up to 4 metres in height with a wing width of 2.5 metres and a weight of up to 500 kilograms. In addition to these, there is a demand for visible profiles that are as small as possible and as filigree as possible.

What do you advise to those who start to build a family home? What should you look out for when choosing materials and manufacturers for windows and doors?

Z. N.: It’s important that the windows and doors are manufactured using quality materials, so if someone chooses aluminium, they will obviously want better quality, durability or dimensions compared to plastic or wood. This is essential in the case of larger dimensions, as only aluminium can be used to create structures of the dimension and weight that would meet the investor’s ideas. However, in addition to a quality product, it is equally important that the customer finds a quality manufacturer to produce and install that structure. No matter how good the product is, if it isn’t manufactured and assembled properly, the finished product won’t function properly and customers won’t be satisfied with it. The expertise and support offered by the manufacturing partner is also very significant. As we see, these houses aren’t always designed through to the details, so the nodes are often missing or, even if they do exist, they’re rough, but there are also examples of nodes that are not technically feasible. It’s very important that designs are reviewed and commented on by a manufacturing partner who can spot these, so the impossibility of the idea’s implementation doesn’t only become apparent during manufacture or installation.

MoreNews